Brushes are sacrificial items and should be replaced when worn to half their original length. The rate of wear should be calculated so that the wear limit will not be reached between inspection periods. Clean the brush holders and commutator with a preparation intended for use on electrical machinery. If old brushes are used, lightly file the flanks at the contact points with the holders to help prevent sticking. New brushes are contoured to match the commutator, but should be fitted by hand. Wrap a length of sandpaper around the commutator—do not use emery cloth—and turn in the normal direction of rotation. Remove the paper and blow out the dust.

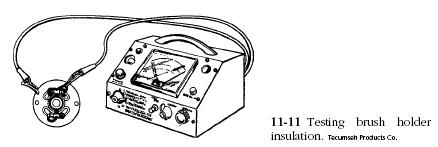

Try to move the holders by hand. Most are riveted to the end plate and can become loose, upsetting the brush-commutator relationship. With an ohmmeter, test the insulation on the hot-side brush holders (Fig. 11-11). There should be no continuity between the insulated brush holders and the end plate. Brush spring tension is an important and often overlooked factor in starter performance. To measure it, you will need an accurate gauge such as one supplied by Sun Electric. Specifications vary between makes and models, but the spring tension measured at the free (brush) end of the spring should be at least 11/2 lb. Some specifications call for 4 lb.

The commutator bars should be examined for arcing, scores, and obvious eccentricity. Some discoloration is normal. If more serious faults are not apparent, buff the bars with a strip of 000 sandpaper. |

![]()