Internal fuel galleries must be flushed before starting the engine. Prime the fuel system and, with the key “off,” disconnect the ECM at the fuse box or harness connector. Remove the combination check valve and pressure regulator, which are located at the rear of the cylinder head at the return-line elbow. Connect a hose to the gallery outlet, and crank the engine in three 15-second bursts, allowing ample time for the starter motor to cool between engagements. Once the galleries are flushed, replace the regulator, make up the fuel-return line and connect the wiring harness to the computer. Run the engine up to operating temperature and check for fuel leaks.

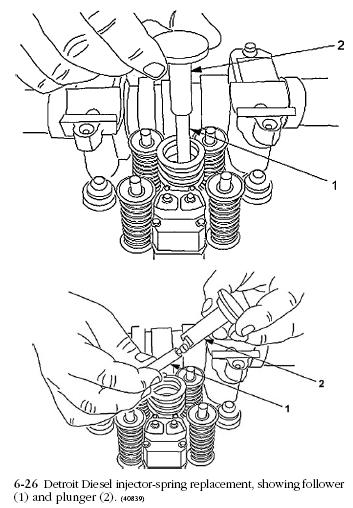

Detroit Diesel supplies an upgrade kit (PN 23528939) for Series 50 and 60 injectors that consists of a spring 11-mm longer than the original, a cam-follower retainer and new hold-down screws. Apparently, the original springs allowed injector plungers to “float” at high rpm. Remove the rocker-arm assembly, place it on a clean surface, and, working with one injector at a time to avoid mixing parts, remove the two 5-mm Allen screws that secure the follower retainer. Lift the retainer and the follower free (Fig. 6-26). Clean the parts in diesel fuel, and install the new spring, follower and retainer, using the screws provided in the kit. Torque to 25–28 N-m (22–25 lb-in.). |

![]()