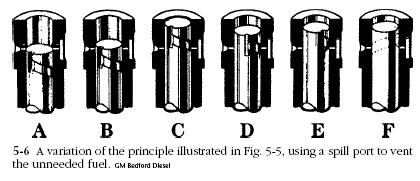

American Bosch, Robert Bosch, and CAV barrels are drilled with a second port above the inlet port to accept spillage during part-throttle operation. Figure 5-6 illustrates the metering action of a CAV pump. Fuel enters the barrel at A and continues to flow until plunger movement masks the two ports (inlet shown on the left, spill port on the right). At full load, the pressure bleed-down through the spill port is delayed until the plunger approaches the end of its stroke, as shown in drawing C. You might wonder why the spill port opens before top dead center (tdc), when a few more degrees of cam movement would raise fuel pressure even more. The reason is that cam-driven plungers behave like pistons, accelerating at mid-stroke and slowing as the dead centers are approached. Opening the spill port early, while plunger velocity and pressure rise are rapid, terminates injection far more abruptly than if the port remained closed until the plunger reached tdc.

plunger pump Diesel Engine Inline Pumps

In drawing D, the annular groove has rotated to the half-load position. The effects of further rotation are shown at E, which represents idle, and at F, shutdown.

However the porting is arranged, the effective stroke has a constant beginning and a variable ending for pumps this book is concerned with. Some marine and large stationary engines meter fuel delivery at the beginning of the stroke.

Details of the mechanism for transmitting rack movement to the plungers vary with the manufacturer, but always include an adjustment to equalize delivery between plunger assemblies. At a given rack position, each cylinder must receive the same amount of fuel. |

![]()