Bosch Injection Pump Delivery Valves

The main function of any delivery valve in the injection pump is twofold:

1. At the end of the plunger’s upward fuel delivery stroke, the delivery valve prevents a reverse flow of fuel from the injection line.

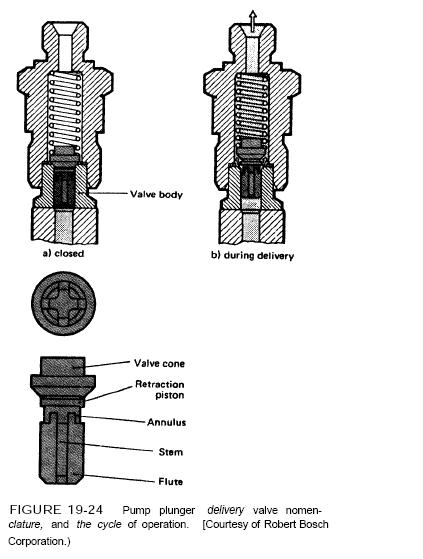

2. Figure 19-24 illustrates the sucking action that occurs at the delivery valve piston portion which controls the residual pressure in the injection line so as to effectively improve the injected spray pattern of the fuel without fuel dribble and possible secondary injection. The sucking action that does occur at the delivery valve therefore effectively reduces the fuel pressure in the injection tube at the end of injection.

Bosch Injection Pump Delivery Valves Bosch Injection Pump Delivery Valves

The delivery valve, or what is sometimes referred to as a discharge valve, is specially designed to assist in providing

a clean, positive end to injection. Below the valve face is a collar that is a precision fit in the valve bore. When pressure is created in the pump above the plunger by the closing of the ports, the valve must be raised far enough off its seat for the collar to clear the bore.

At the end of injection when pressure in the pump chamber is relieved by the opening of the control port, the valve drops down on its seat assisted by spring pressure. A volume of fuel equal to the displacement volume of the valve is added to the line and nozzle, reducing this pressure and allowing the nozzle valve to snap shut without the cushioning effect of pressure retained in the line and nozzle, such as with the closing of an ordinary valve. This is commonly called line retraction, which lessens the possibility of secondary injection or after-dribble at the spray nozzle. It is accomplished by an antidribble collar (accurately fitted relief or displacement piston) located at the upper end of the valve stem just below the seat. |

![]()